Modern recycling and waste diversion has come a long way since the incinerator. Science and engineering have helped create effective and powerful methods for dealing with waste, and one of those components that is gaining popularity is the waste-to-energy-plant.

You might be saying, “Really? Isn’t waste supposed to be well...waste?” That’s true, but now we have methods and processes for dealing with waste in a way that is beneficial to everyone, and many waste-to-energy companies are making enormous strides forward with technology. Let’s find out more, and we’ll be sure to answer the big question: “How to generate energy from waste?”

What is a waste-to-energy plant?

Simply, waste-to-energy plants are facilities that combust waste to produce electricity. A simple way of thinking about it is turning trash into power.

Compared to the incinerators of decades ago, which often did not produce power at all, most waste-to-energy plants sort the waste that they receive into recyclable and non-recyclable materials before combustion, so that materials are optimally diverted to where they can be of most use.

And, you might not realize the volume of the recycling that is taking place. Recently, the EPA reported that the U.S. sent around 32.66 million tons of waste to facilities that converted the refuse into energy. That is quite a bit of waste that’s being turned into usable energy.

As a general concept, waste-to-energy is part of a general waste diversification strategy, which is an attempt by cities and municipalities to reduce and diversify the ways in which waste is created and disposed of. It isn’t the be-all-end-all, but the process can help ensure that less waste is produced overall, and more ends up being used.

Now, how does it work?

The nuts and bolts

At the majority of most waste-to-energy facilities, waste is transported to the site, where the processing begins. Some facilities accept hazardous and industrial wastes, which we won’t cover here.

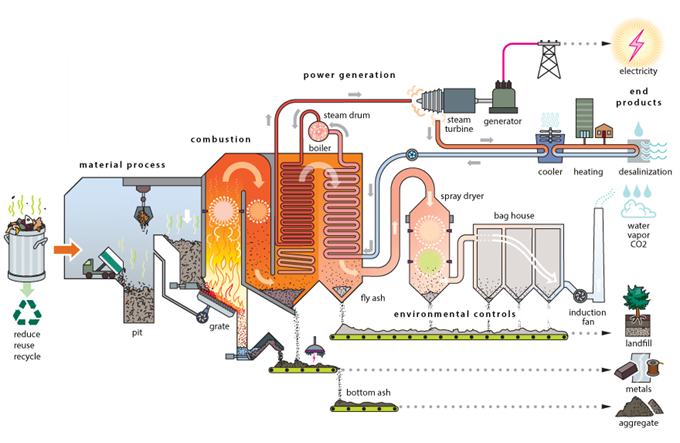

To begin, materials are brought to the facility, where any waste that is recyclable or can be diverted before combustion is sorted out. Then, waste is transferred into a pit which is fed into a grate. The grate gradually feeds the waste into an incinerator, which combusts it into heat, which then feeds to a boiler. The boiler generates steam, which powers a steam turbine, ultimately resulting in electricity.

But, that’s just the power generation component. There’s more to the process beyond electricity. Ash that results from the combustion can be taken to landfills, and metals that sink to the bottom can often be gathered and reused. We’ll talk about the fumes that result from burning in a moment.

Where are they located?

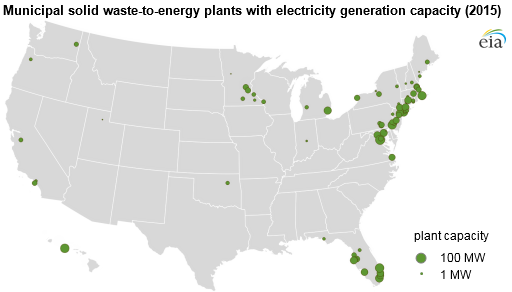

Waste to energy plants are hardly widespread in the US. There are a number of reasons for this, which we’ll get into in a little bit, but the trend is starting to catch on as the country pivots toward creating better infrastructure to support them.

As of 2015, the US has 71 waste-to-energy plants. These plants account for a small amount of electricity generation (around 0.4%). The vast majority of these plants are located in Florida, but many states are planning or thinking about expanding their infrastructure to accommodate waste-to-energy.

Pros and cons

So, let’s get into what many see as the positives and negatives of waste-to-energy:

Pros:

- Low overhead - Many waste-to-energy plants utilize, well, waste, so the cost of purchasing fuel is almost nonexistent. Waste is not a costly fuel source.

- Low cost to build - Most waste-to-energy plants cost around 440 million dollars to build, which is a lower cost than many other types of waste facility.

- Waste diversion - When supported by the proper infrastructure, waste-to-energy facilities can be an integral part of a waste diversion program, which plays a big part of keeping waste out of landfills and placing it back into the cycle of reuse.

- Energy production - Usually, a well-designed and functional waste-to-energy plant can produce around 400GWh annually, which is a significant amount of electricity.

Cons:

- Costly infrastructure - One of the reasons that waste-to-energy plants are not as widespread as other forms of waste diversion is due to the high costs of developing and maintaining infrastructure for them. Transportation, sorting, grading, and operations costs for a waste-to-energy plant are not small, and they often require heavy initial investment to get off the ground. With many cities in the US creating their own waste management plans, whether or not this particular mode of diversion can happen is often implemented on a case-by-case basis.

- Pollution - While waste-to-energy plants generate less pollution than coal plants, the fumes and pollutants they can generate are not easy to ignore. Dioxin and furan emissions are common, which are both harmful pollutants. However, many facilities have developed systems and technology to reduce the overall harm, and the impact is small compared to some of the impacts of other waste disposal methods.

Learn more

If you’re interested in learning more about waste-to-energy plants, the Energy Recovery Council’s website is a great place to start. Their stance on municipal solid waste is eye-opening, and there’s tons of information to be learned.

And, if you’re just looking for a way to improve your own trash disposal, get in touch with us, and browse some of our waste receptacles while you’re at it.

Images Cited